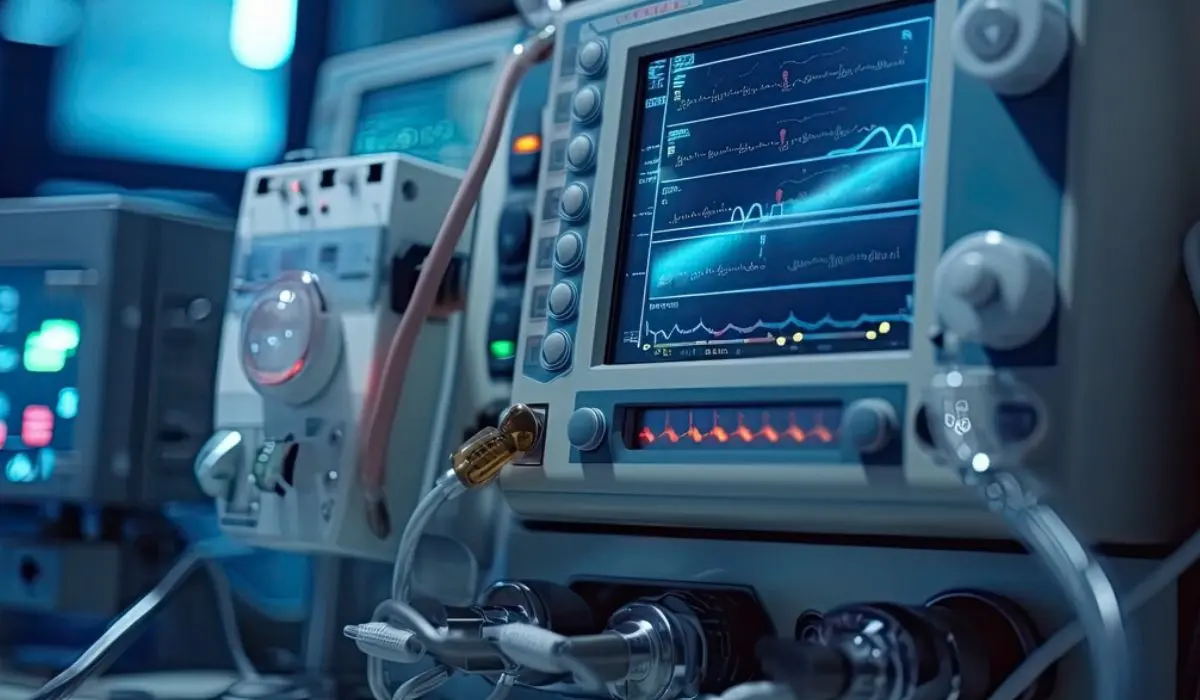

A medical device is basically any instrument used for medical purposes. Now designing such a piece of equipment is what we call medical device designing. Medical device designing is the first step in making a new device. You need a design or a blueprint to see an idea coming to fruition.

The goal here is to make something that is easy to use, catering to the needs of the users and there is also an element of being aesthetically pleasing as well.

What Is Medical Device Designing And How Do You Make One?

Medical device design is not an easy process. It demands a thorough understanding of engineering principles, innovative thinking, an in-depth understanding of medical procedures, and much more.

There are so many nuances to this process that one must keep in mind. Since this field is very close to the health and well-being of humans there are risks attached to it. There is much more to this process than coming up with an idea, developing it, and then distributing it.

Designing and developing go through many revisions and scrutiny. This process needs to be completed in ultimate adherence to regulatory boards. Plus the device must ultimately be safe and effective and it must be something that is manufactured understanding the concerns of the user.

This article will give you a brief overview of all the aspects that one must keep in mind before making one design. Let’s jump right into it without further ado.

How To Design A Medical Device?

Medical devices are integral in making medical intervention safe and easy. But as mentioned before this process is not without its risks. So let us go through some key ideas that are considered to reduce the risky aspects and to ensure maximum safety as well as feasibility be it for the users or from the business standpoint.

✅ User Requirements

It goes without saying that developing user-friendly equipment requires keeping your user needs and demands in mind. So designing equipment requires thorough research analyzing the user demand, preferences, and challenges they face and addressing them innovatively.

Conducting surveys, collecting reviews, interviews, etc might be useful in this pursuit. With the collected data designers can get a clear idea of how to provide solutions to the limitations they face and develop a unique design addressing the challenges.

✅ Design Controls And Regulatory Compliance

Boards like the FDA have certain regulations and standards that a design is expected to meet. So design developers must be really careful when it comes to creating design and should ensure that the requirements set by the boards are met. Or else there might consequences like withdrawing your product from the market which might cost manufacturers a lot.

So developers must make sure that they have a clear idea about the requirements set by the boards in the countries that they are planning to introduce the device. Plus the major aspect is not just about the possible losses but the safety and efficacy of the product. The rules are set there to manage risks and ensure that certain requirements are met. This design control process comprises risk management, design verification, validation, and design transfer.

As said before this can be a risky process and there are regulatory boards like the FDA, EMA (European Medicine Agency and similar international boards like ISO (International Organization for Standardization). We will see some of the regulations set by ISO for the safety and effectiveness of a design.

👉 ISO 13485: These are the set of specifications for quality management systems for medical devices. This covers many details from designing and development to the life cycle of the devices and production, installation, and servicing.

👉 ISO 14971:2007: These rules and regulations majorly cover the risk management aspects of a medical device. This rule entails specifics for identifying possible hazards, estimating and evaluating them to control these risks, and ensuring safety and efficacy as well.

✅ Prototype Development

A prototype is a sample, model, or preliminary version of a product. This might help the user get a better vision of the product. Building prototypes may help with studying the functionality, observing the flaws, studying more ways to correct them, and seeing what changes can be made to make it the best version possible before going for large-scale production.

There are many methods to create a prototype like 3D printing, injection molding, and machining. This is important to the verification and validation part of the design. Once the prototype is made and the features of the design are ensured to be feasible then it is put under the concept freeze phase. This means that the model is finalized and no more revisions or changes are required.

Also Read:- Why You Need Fiber? How To Make High Fiber Smoothie?

Final Thoughts

Designing a medical device is not an easy task. It requires engineering skills, adhering to guidelines, and a lot of improvising and addressing limitations to build a practical design that is profitable. It is more than just coming up with a design, producing it, and selling out to users.

This process is complicated and requires a detailed study of the user needs, regulations set by medical boards, and a lot more.